CUSTOM "HOLOGRAM" LINE ART DISPLAY

Instead of purchasing gifts for loved ones during the 2022 Holiday season, I instead used any time not spent studying to design and build them. The resulting electronics project is a fully custom light display for the vector line art portraits I made of my family.

I designed every aspect of the system from scratch, and used only free components and resources available at Penn makerspaces. The underlying electronics is fully analog (no microcontroller) as I wanted to keep the circuit simple and cheap across 3 copies. The array of 12 LEDs which shine up through an engraved acrylic panel is powered by a potentiometer and MOSFET-based dimming circuit I designed. I modeled the black base in SOLIDWORKS as a single piece which can be printed with minimal supports. The clear acrylic panels were laser cut and vector etched from a template I created in Illustrator.

Something I love about the design is that engraved panels can be cut in a matter of minutes and easily swapped! With access to a laser cutter and some vector art skills, making them is trivial. I hope to make more panels for my family as I create even more artwork!

SAFECRATE

NC STATE ENGINEERING ENTREPRENUERSHIP PROGRAM 2020

WINNING VENTURE!

In the United States, households with a pet have come to outnumber those with children, and there is a market trend towards higher spending, especially on pet health products. It is also reported that nearly half of all dogs experience anxiety, many cases of which are caused by loud distressing sounds. As a part of the NC State Engineering Entrepreneurs Program (EEP), my team worked to develop a dog crate that provides a quieter and more acoustically-stable environment for pets which creates more relief than current products. Our product, SafeCrate, effectively addresses the root causes of noise anxiety, yielding a novel product that will undoubtedly attract pet owners. SafeCrate is an enclosure that utilizes Passive Noise Cancellation (PNC) and noise masking technology to limit the effect of distressing ambient sounds on pets.

Initially, our team intended to primarily rely on Active Noise Cancellation (ANC) technology not unlike what is commonly being implemented in state-of-the-art headphones and the cabins of several new lines of vehicles. We even created our own analog ANC signal-inverting circuit during the earlier prototyping phase, but found it to be ineffective at canceling sound uniformly in an open volume. This type of system was promising because it works exceedingly well for low frequency sounds such as fireworks and thunder which are the most notorious distressing sounds for many pets. However, a more effective digital ANC system run by a microprocessor would be exceedingly complicated and could realistically double production costs for the crate. This, along with research indicating that noise masking could provide adequate relief to animals, led the team to cease development of an ANC system in favor of the less complicated and more effective noise masking solution.

The team shared responsibilities in all areas, from researching the engineering principles involved to intensive market research. However, I was responsible for creating all graphic and video content, as well as final design and primary CAD modeling of our finished prototype MVP.

PROTOTYPES

ELECTROMAGNETIC CLAMP DESIGN

ECE 535 FINAL PROJECT (NCSU 2020)

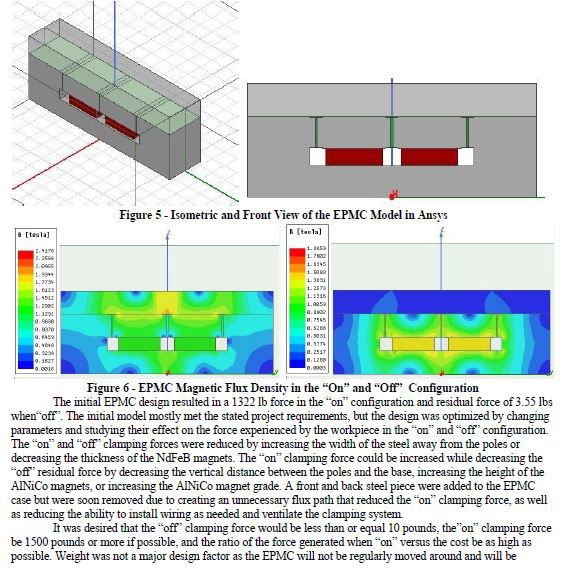

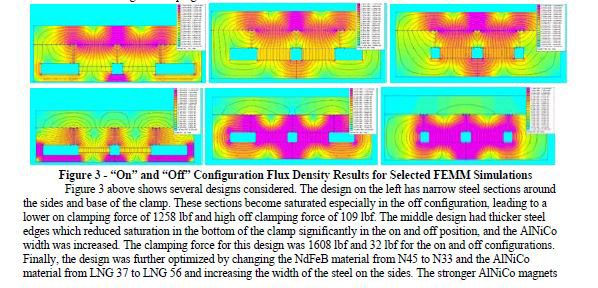

As a final project for ECE 535: Design of Electromechanical Systems, a graduate course taught by Dr. Gregory Buckner, students were tasked with designing an electro-permanent magnetic clamp (EPMC) that could be used to immobilize a metal work-piece during the machining process. The benefit of EPMCs is that they require no power draw in either ON/OFF configuration, yet still achieve strong clamping forces on ferromagnetic materials. They rely on both rare earth (AlNiCo) magnets and weaker ceramic magnets that can flip polarity to switch between clamp ON and OFF states. The ultimate goal was to maximize ON configuration clamping force while keeping OFF configuration forces below a certain threshold.

My team, comprising three undergraduates and one graduate student, worked remotely to develop an EMPC that far surpassed the minimal requirements and featured a robust technical analysis and report. My responsibilities included modeling the system in FEMM (a free finite element electromagnetic modeling software), and developing a methodology to select the attributes of the electrical and magnetic system required to switch between the two clamping states.

Final comments from Dr. Buckner included:

“Very impressive use of analytical and computational methods… Overall, very thorough and correct technical aspects. I’ll be surprised to see a more comprehensive project than this… excellent!”

“The aforementioned technical methods… were novel, impressive.”

ROBOTIC END EFFECTOR RESEARCH

OREGON STATE UNIVERSITY 2019

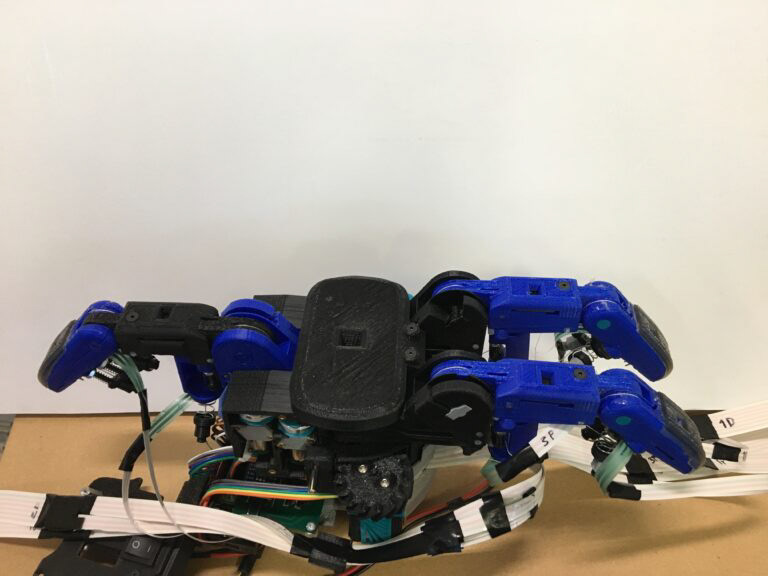

By the summer of 2019, my desire to enter the field of robotics had reached its pinnacle, as had an affinity for biologically-inspired design. Fortunately, I discovered an excellent REU program at the Collaborative Robotics and Intelligent Systems Institute at Oregon State University. The department featured many biologically-inspired research projects, from an artificial spider web that could detect the exact location and intensity of a disturbance, to a surgical implant designed to reproduce lost tendon strength in hands. It also featured other labs focused on topics like soft robotics, human-robot interaction, and grasping and manipulation.

I was brought on under Dr. Cindy Grimm in the grasping lab, and I was tasked with developing the capabilities of a fully-actuated robotic hand for use in a series of automated grasping tasks. These tasks would be designed to evaluate the feasibility and success rate of a variety of novel grasping strategies made possible by full actuation of each finger on the hand. The model had been partially developed with the same geometry of a readily available under-actuated robotic hand, the Barrett Hand, which would act as the baseline for grasping performance. During my time there, I achieved a fully operational and responsive hand that is now being used by the lab for further experimentation. The lab hopes to be able to replicate grasps performed by human subjects using a puppet hand model and achieve high success rates in grasping and manipulation tasks not possible with under-actuated versions of the hand or other end effectors.

The video below shows my early testing after mapping control of the hand to a nanoKontrol MIDI board to allow for fine-tuning and automated positioning.

SUBARU OUTBACK BED PLATFORM

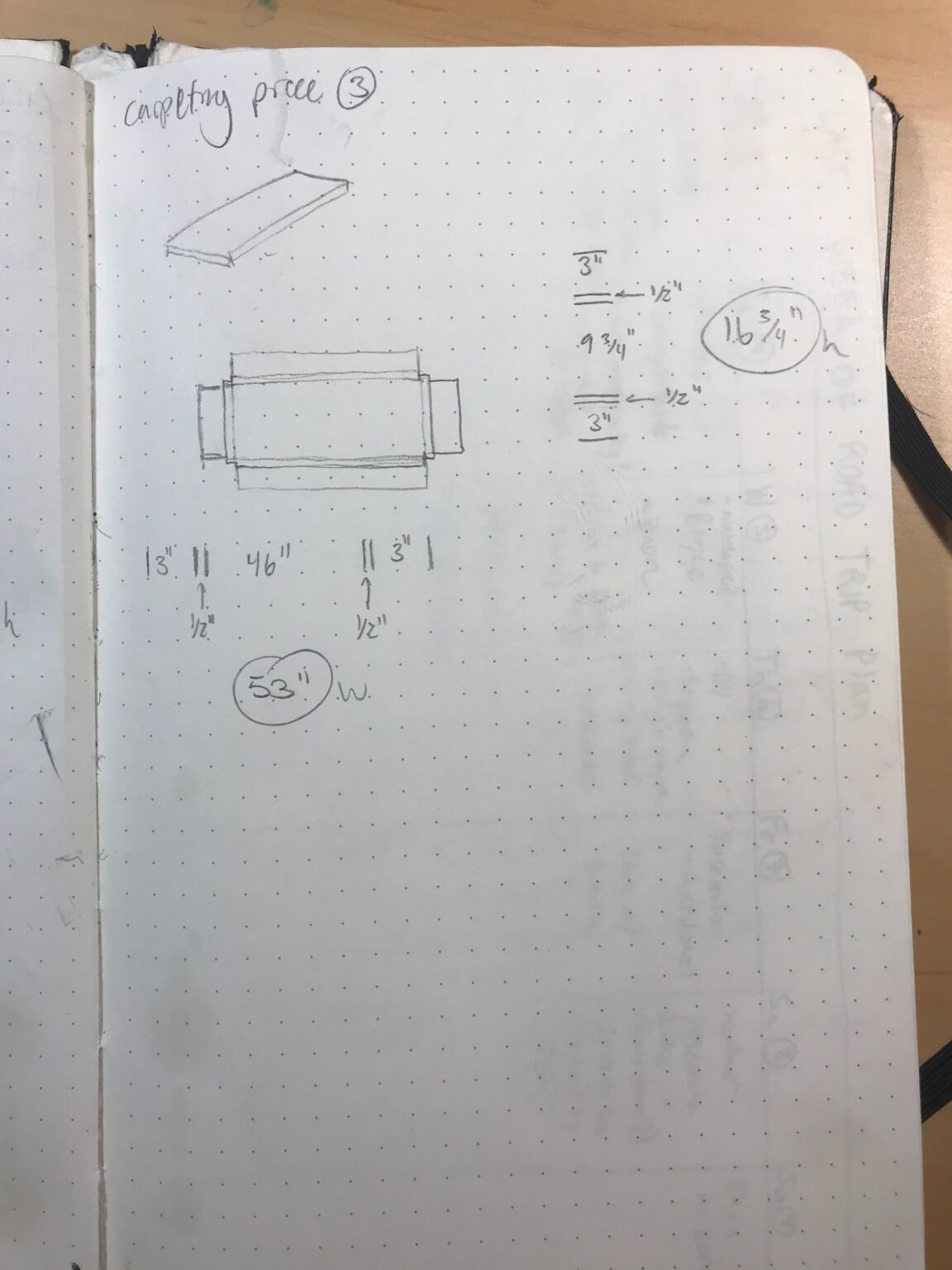

Prior to my research internship in robotics at Oregon State University in June 2019, I built a car camping bed platform from scratch that would allow me to complete a long-distance road trip on my way to and from Oregon.

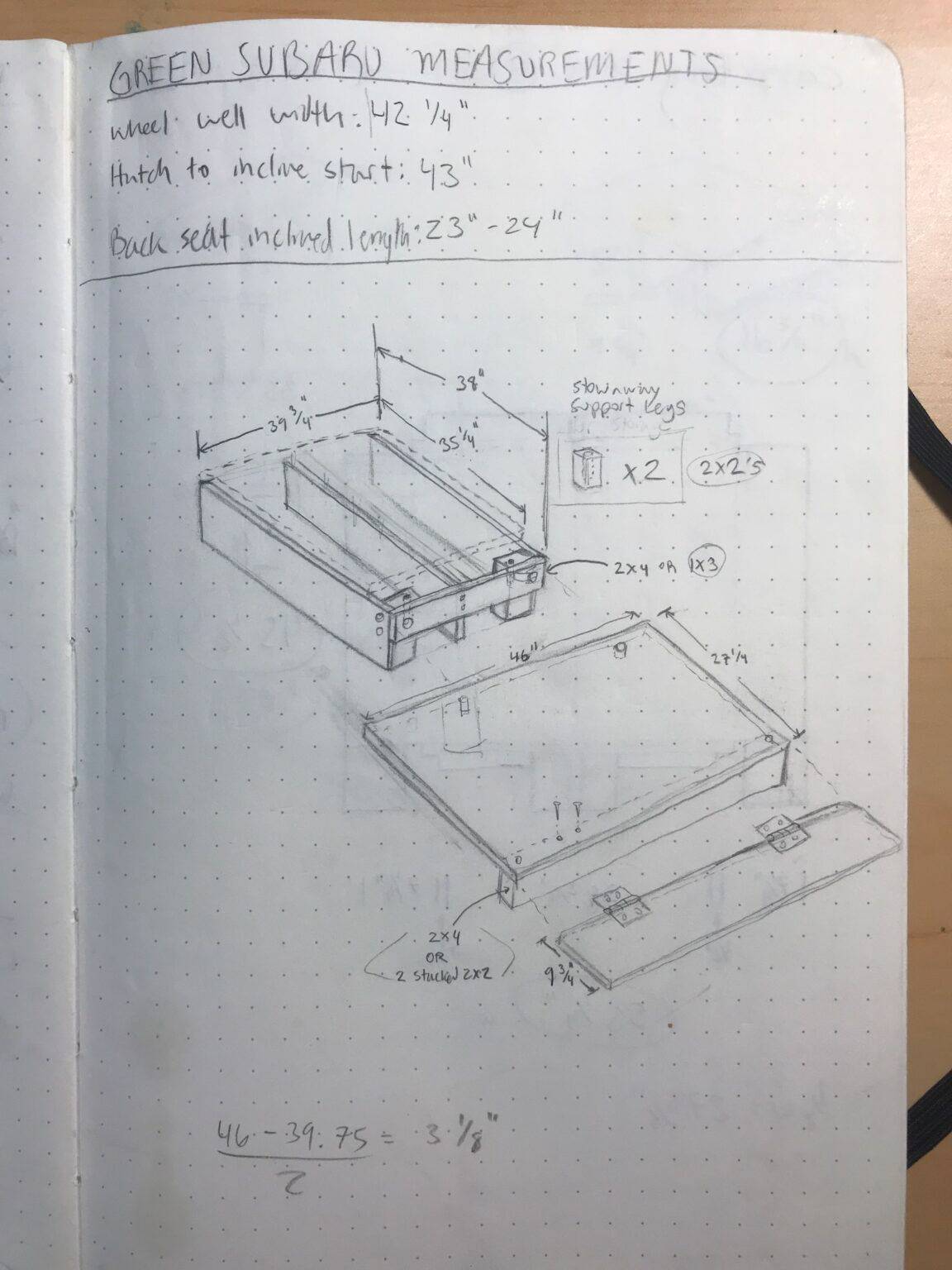

The design is unique for several reasons. it provides ample storage centered around two long, sliding containers without sacrificing strength. It is also precisely carpeted to ensure user comfort and surface protection. The most important feature, however, is its modular, stacking design that allows the back seats of the vehicle to be set in upright position when the bed platform is not necessary. The transition between stowed and deployed platform takes less than one minute, and the stacked upper half provides shelved storage in the hatch. Therefore, with the system still in the car, I do not have to sacrifice storage or passenger capacity.

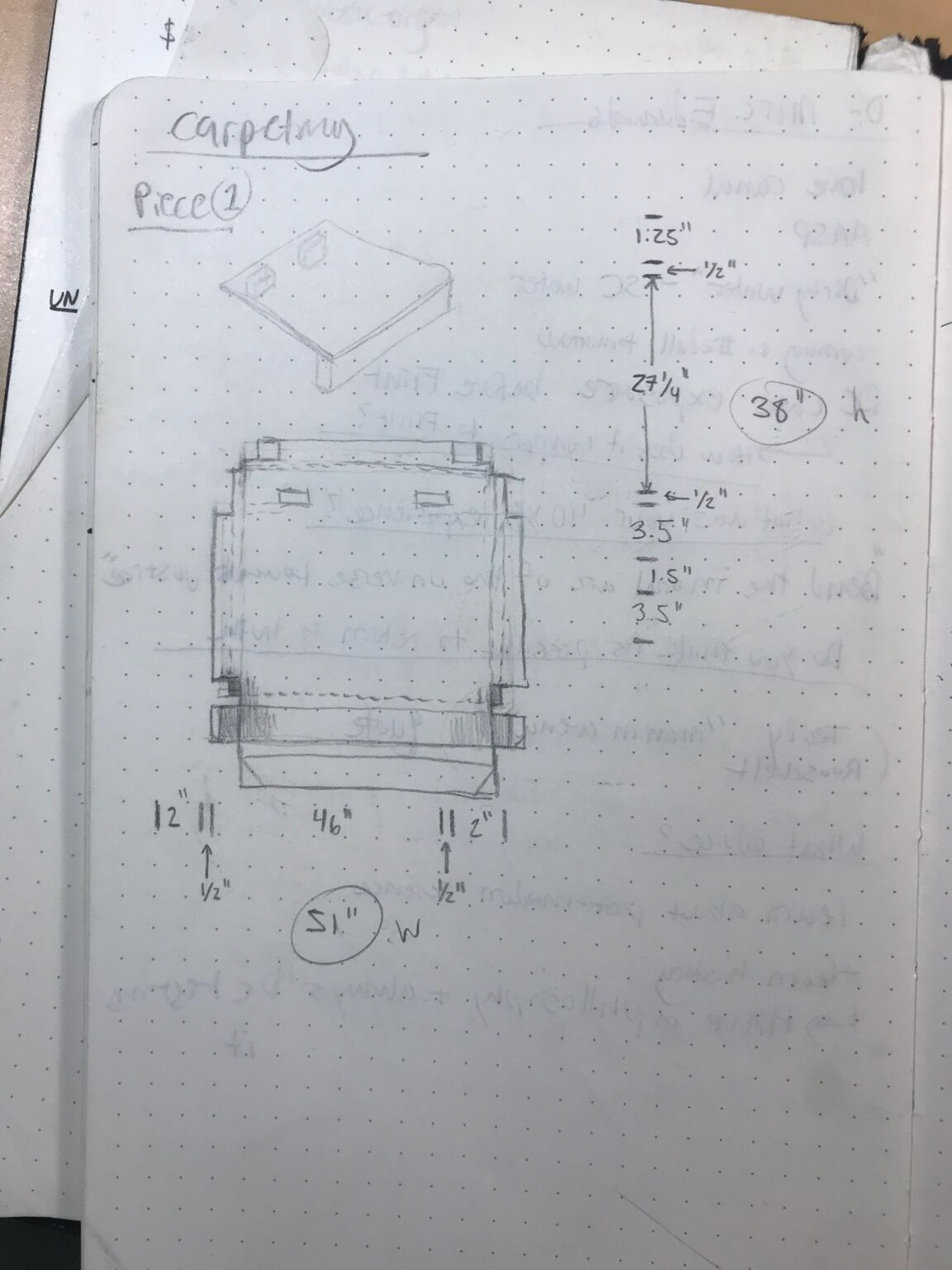

TECHNICAL SKETCHES

FINISHED MODULAR PLATFORM

Make-a-thon (NCSU 2018)

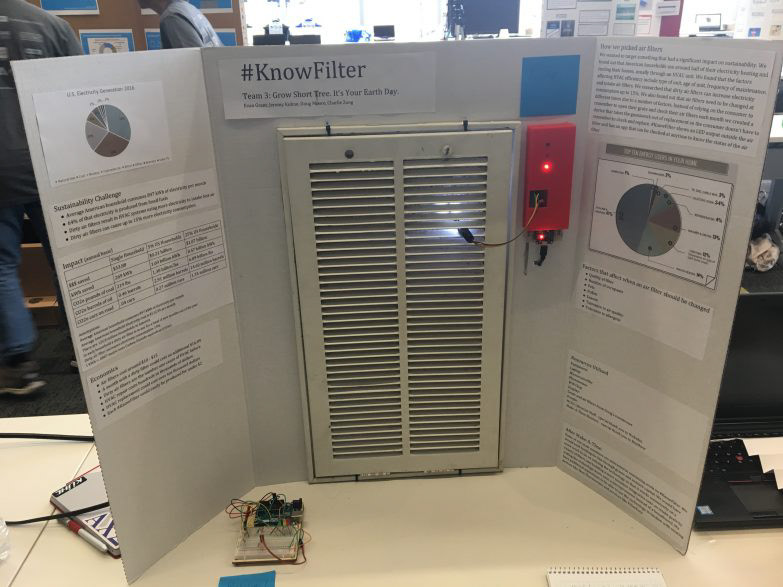

Make-a-thon is a “hack-a-thon” inspired competition hosted annually by the NC State Sustainability Office. Participants have only 48 hours to ideate, prototype, and pitch their sustainable product venture. The final pitch is performed on stage for all participants, event organizers, and judges. This served as my introduction to entrepreneurship at NC State, and allowed me to practice communicating technical information to a large audience.

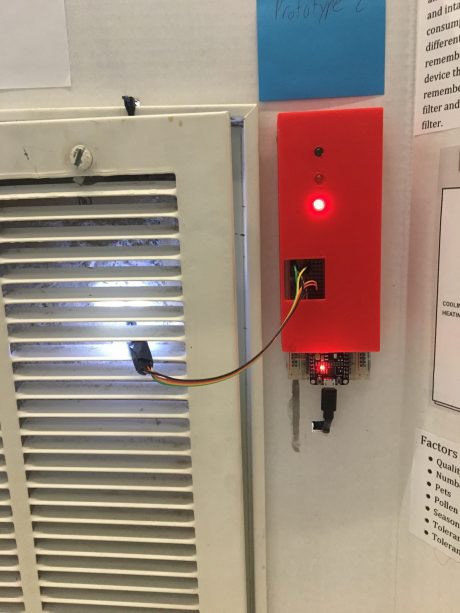

My team and I ultimately created an internet-enabled home air filter quality detector that alerts a homeowner when filter replacement is required. This device would take the guesswork and forgetting out of replacing air filters, which would inevitably lead to significant long-term energy savings and promote the health of HVAC systems which are costly to repair. Our proposed venture included not only the physical device, but additional functionality to automate filter replacement through a subscription service that would ship new filters directly to the user.

Our prototype was created using a microcontroller with a custom light sensor to roughly determine the progression of particulate buildup on the surface of the filter. a user would be notified via a mobile application if the sensor value reached a certain threshold. While we did not place at this competition, we were met with an overwhelmingly positive response from judges and Sustainability Office staff. One facilities manager at NC State even approached our team and congratulated us for arriving at a novel idea which he felt could be implemented to great success at not just the residential scale, but even industrial applications such as the university.